Bind the lower members of seismic isolator with steel bars and pour concrete to 20 mm below the lower pre-embedded plate. Pre-holes are reserved in the size of twice diameter of the anchoring steel rod.

Bind the lower members of seismic isolator with steel bars and pour concrete to 20 mm below the lower pre-embedded plate. Pre-holes are reserved in the size of twice diameter of the anchoring steel rod.

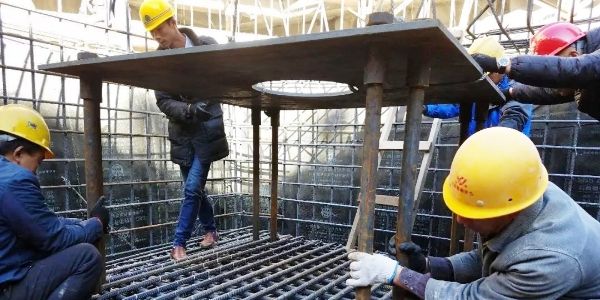

Calibrate the elevation and axial location of the lower pre-embedded plate. Bind the reinforcement mesh of lower member and place the lower pre-embeded plate into designed position. Level and fix the plate and erect formworks for secondary pouring preparation.

Conduct secondary concrete pouring into the lower members, vibrate for compaction and dismantle the formwork.

Put the seismic isolator in place and fix it.

Install the upper pre-embedded plate.

Bind the upper member of seismic isolator with steel bars and pour concrete.